In regard to personal air sampling, the more air you move, the better your chances of detecting low-level contaminants. While this principle might seem like common sense, it is often overlooked. For example, many industrial hygienists stick with standard flow rates without considering how increasing sample volume can dramatically improve their limit of detection (LOD). Let's explore why sample volume is important and in which scenarios increasing the flow rate or sampling time is a viable solution.

The Math and Science Behind Sample Volume and LOD

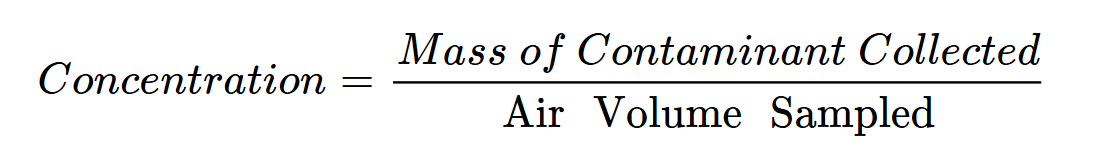

Every analytical method has a minimum detectable mass—the smallest amount of a contaminant the lab can confidently measure. This lowest detectable mass is used in conjunction with the volume sampled. To calculate this concentration, we use this basic equation:

So, what happens when we increase air volume? If we pull more air through the sampler, we’re collecting more contaminant, making it easier to reach that minimum detectable mass. Doing so effectively lowers the limit of detection, allowing us to measure smaller concentrations that might otherwise have been missed.

When you're looking for a needle in a haystack and only grab a handful of hay, your chances of finding the needle are low—but if you sift through more of the stack, you improve your odds of finding what you are looking for. Air sampling works the same way. The more air you pull, the better your chances of detecting low-level contaminants that otherwise might be missed. By increasing air volume, you collect more contaminant. This makes it easier to reach the minimum detectable mass, thereby effectively lowering the limit of detection and allowing you to measure smaller concentrations that might have gone unnoticed.

Let’s look at an example:

| Flow Rate (L/min) | Sampling Time (min) | Air Volume (L) | Cubic Meters (m³) | Minimum Detectable Mass (µg) | LOD (µg/m³) |

| 1 L/min | 100 min | 100 L | .1 | 1 µg | 10 µg/m³ |

| 2 L/min | 100 min | 200 L | .2 | 1 µg | 5 µg/m³ |

| 4 L/min | 100 min | 400 L | .4 | 1 µg |

2.5 µg/m³ |

By doubling or quadrupling the flow rate, we significantly lower the LOD, making detecting contaminants at low concentrations easier.

The Catch: You Can’t Always Increase the Flow Rate

Before you crank the pump to full blast, remember that some sampling devices are designed to work at specific flow rates. For example, if you’re using a traditional cyclone for respirable dust sampling, increasing the flow rate beyond the recommended range will throw off the particle size cutoff, making your data invalid.

So, what’s the solution when you need more volume but can’t increase the flow rate, as is the case when using a traditional cyclone?

Enter the SKC PPI Samplers: Higher Flow Without Compromising Collection Efficiency

The SKC Personal Parallel Impactor (PPI) provides the optimal solution for this scenario. Unlike traditional cyclones, the PPI is available in 2 L/min, 4 L/min, and 8 L/min models, allowing for a wide range of flow rates while maintaining the precise cut-point and the correct collection efficiency for respirable particulate sampling. That means you can increase your total sample volume, lower your LOD, and get better data at lower dust concentrations—without compromising accuracy.

Increasing Sample Volume for Chemical Sampling

Particulate sampling isn’t the only area where increasing air volume improves detection limits. When collecting chemical contaminants, higher sample volumes can also lead to better sensitivity—especially when using charcoal or thermal desorption tubes.

When sampling chemicals, increasing air volume is just as important. For example, charcoal tubes used for chemical sampling typically operate at flow rates between 20 and 200 ml/min. While extending sampling time can help collect more contaminant, increasing the flow rate might cause excessive back pressure or breakthrough, where the compound moves past the sorbent bed and is lost. A simple solution is using a larger sorbent tube, like the SKC 226-09 tube, which has increased capacity and allows for sampling rates up to 1 L/min without increased back pressure or breakthrough issues.

Another approach is thermal desorption tubes, which are designed for extremely low detection limits. Unlike liquid extraction methods that analyze only a small portion of the sample, thermal desorption tubes allow the entire collected sample to be injected into the gas chromatograph (GC). This results in significantly improved sensitivity, making it possible to detect contaminants at parts-per-billion levels.

Conclusion: More Air, Better Sensitivity

By selecting the right sampling media and optimizing both flow rate and sampling duration, industrial hygienists can maximize sensitivity and ensure accurate exposure assessments, even for low-concentration contaminants. The key takeaway for industrial hygienists looking to optimize their sampling strategy is that more air means better detection. Whenever possible, consider increasing sample volume to improve data quality. When traditional samplers limit your options, tools like the SKC PPI Samplers for particulates and larger sorbent tubes like the 226-09 or 226-300 Series thermal desorption tubes for chemicals can help achieve lower detection limits without sacrificing accuracy.

Better sampling leads to better decision-making, and that’s what industrial hygiene is all about.

Dusty Ott, CIH, is Corporate Industrial Hygienist for SKC Inc. He is based in Ogden, Utah, where he and his wife (also an industrial hygienist) are raising their family of four children. Dusty is passionate about making industrial hygiene concepts easy to understand at all levels. Follow Dusty on LinkedIn

.png)