Passive Thermal Desorption Tube for Benzene, pk/10

Passive Thermal Desorption Tube for Benzene, pk/10 Overview

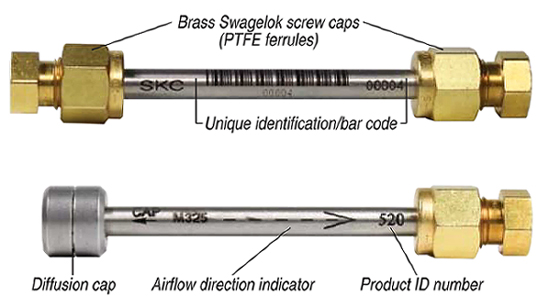

3.5 x 0.25-in OD deactivated stainless steel tubes filled with pre-conditioned Carbopack X and supplied with diffusion caps and brass Swagelok screw caps with PTFE ferrules

For continuous monitoring of benzene at refinery fenceline locations using EPA Method 325. May be used also for other VOCs of concern, including HAPs. See Technical Note: Validated Uptake Rates for Benzene and Other VOCs Using the SKC Passive TD Tube (PDF)

Performance Profile

| Sorbent | Carbopack X, Anasorb GCB1 (see Reference) |

| Tube Material | Stainless steel coated with SilcoNert 2000, sealed with brass Swagelok screw caps fitted with PTFE ferrules |

| Uptake Rate | Carbopack X: Benzene 0.67 ml/min Anasorb GCB1: Benzene 0.63 ml/min |

| Dimensions | 3.5 x 0.25-inch OD (Sized for Perkin Elmer and Markes International Thermal Desorbers) |

| Analysis | GC-FID or GC-MS (EPA 325B) |

Note: All tubes are conditioned and quality control tested to assure low background.

Reference

McClenny, W.A. et al., “24 h Diffusive Sampling of Toxic VOCs in Air onto Carbopack X Solid Adsorbent Followed by Thermal Desorption/GC/MS Analysis–Laboratory Studies,” J. Environ. Monit., Vol. 7, Issue 3, 2005, pp. 248-256

Technical Note: Sampling Rates for Benzene and Other VOCs Using the SKC Passive TD Tube (PDF)

Federal Register, Vol. 80, No. 230, 40 CFR Parts 60 and 63, www.gpo.gov/fdsys/pkg/FR-2015-12-01/pdf/2015-26486.pdf

EPA Method 325A, Volatile Organic Compounds from Fugitive and Area Sources, (sampling), https://www3.epa.gov/ttn/emc/promgate/m-325a.pdf

EPA Method 325B, Volatile Organic Compounds from Fugitive and Area Sources, (analysis), https://www3.epa.gov/ttn/emc/promgate/m-325b.pdf

- Tube Type : Passive Thermal Desorption

- Sorbent : Other

- Sorbent Coating : No

- Number of Sections : 1

- Tube Material : Stainless Steel

- Passive Sampler Use : Benzene

- Passive Sampler Use : BTEX

- Passive Sampler Use : HAPs

- Passive Sampler Sorbent : CarboPak X

- Validation Level : OSHA

- Validation Level : EPA

Product Document

Operating Instructions - Passive Thermal Desorption Tubes 226-520 and 226-521 (PDF)

Passive TD Tube for Benzene Spec. Sheet (PDF)

Tech Note: Validated Uptake Rates for Benzene and Other VOCs Using SKC Passive TD Tubes (PDF)

226-520 Tube for BTEX and other VOCs Laboratory Reference List